As a procurement manager, you know that even the smallest components can have the biggest impact on patient safety, clinical efficiency, and your bottom line. I’ve seen this choice impact everything from medication waste to staff safety, so let’s clear up the confusion and give you a framework for making the right call, every time.

The Quick Answer: Luer Lock vs. Luer Slip at a Glance

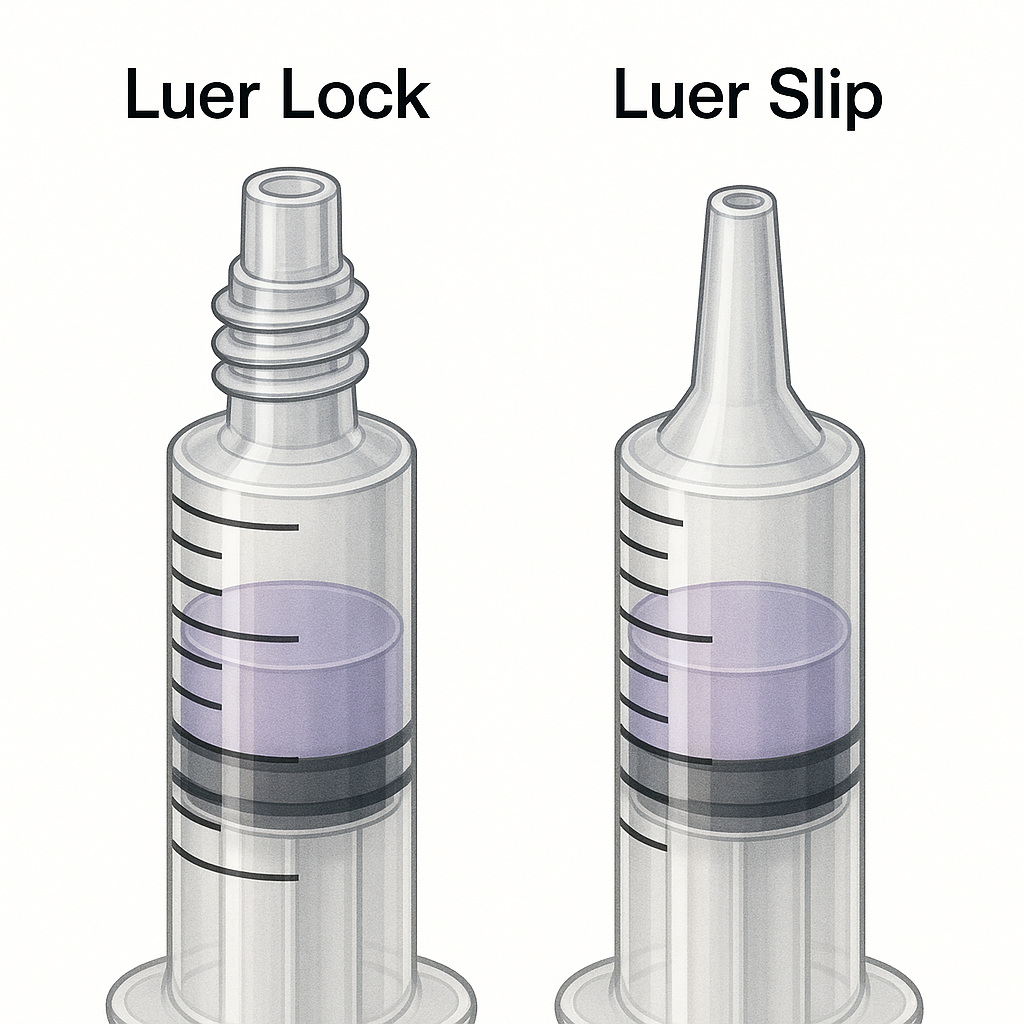

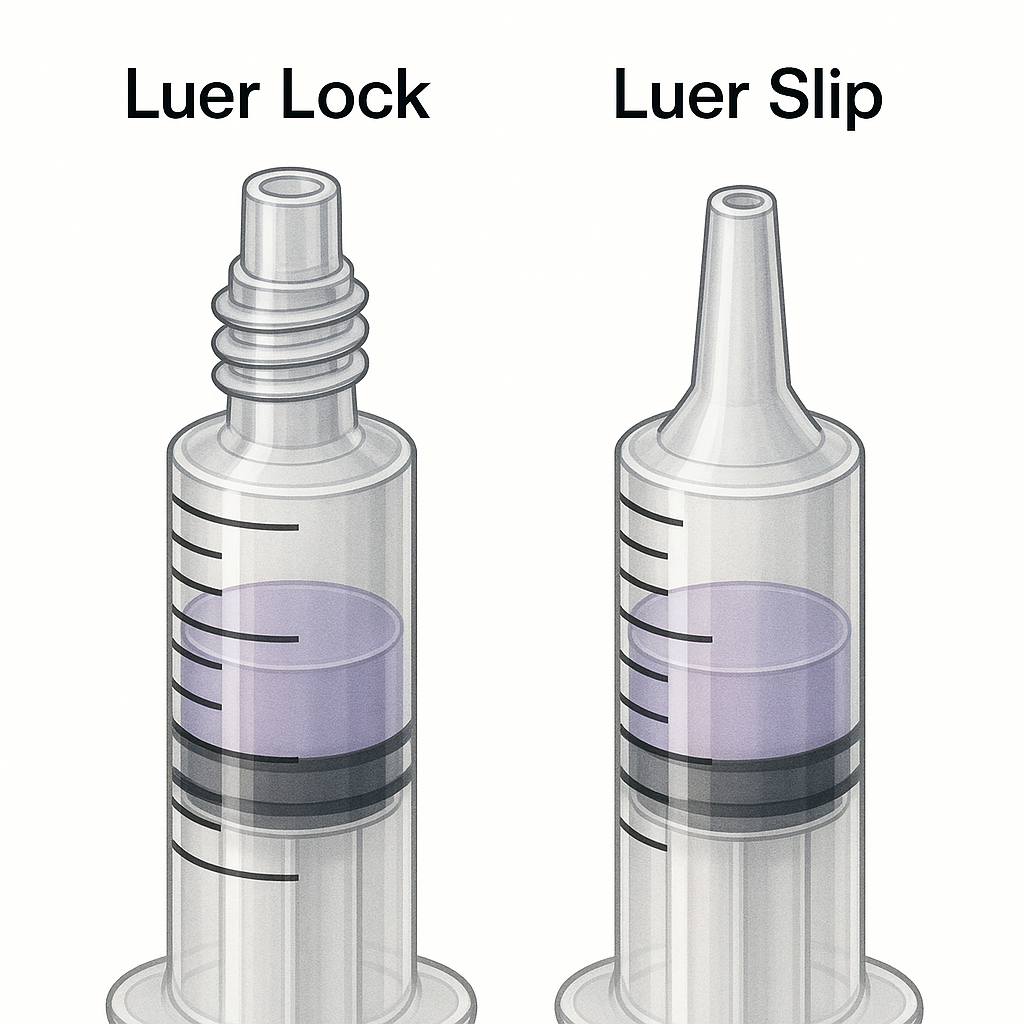

For procurement professionals in a hurry, here’s the core difference: Luer Lock syringes feature a threaded tip that allows a needle to be screwed on, creating a secure, leak-proof connection ideal for high-pressure, critical, or hazardous fluid applications. In contrast, Luer Slip syringes use a simple friction-fit (push-on) connection that is faster for assembly, making them a cost-effective choice for low-risk, low-pressure, routine injections like vaccinations.

| Feature | Luer Lock Syringe | Luer Slip Syringe |

|---|---|---|

| Connection | Threaded, twist-on | Friction-fit, push-on |

| Security | Excellent (Prevents leaks & disconnections) | Fair (Relies on friction) |

| Best For | High-pressure, viscous, or hazardous fluids | Low-pressure, routine injections |

| Speed | Slower to attach | Faster to attach |

| Cost | Higher per unit | Lower per unit |

The Foundation: What is a “Luer” Connection Anyway?

Before we get into the versus, let’s talk about what these two syringe types have in common. Both use the standardized Luer taper system. Think of it as a universal language for medical connectors. This brilliant, yet simple, design was invented in the late 19th century and consists of a standardized 6% taper on the male fitting (the syringe tip). This taper fits perfectly into a corresponding female part (the needle hub).

Why does this matter to you as a procurement manager? Interoperability. This standardization, now governed by ISO 80369 standards for small-bore connectors, means you can confidently source ISO-compliant needles and syringes from different manufacturers knowing they will fit together. It’s the cornerstone of a flexible and resilient supply chain, preventing you from being locked into a single proprietary system.

Deep Dive: Luer Lock Syringes — When Security is Non-Negotiable

A Luer Lock syringe is easily identified by the plastic threading or sheath that surrounds the tapered tip. This isn’t just for show; it’s a critical safety feature. You don’t just push the needle on; you give it a firm twist, and the threads on the needle hub lock into the syringe, creating a solid, unified instrument.

Key Advantage: A Secure, Leak-Proof Seal

The twist-lock mechanism is the Luer Lock’s superpower. In my experience, this feature is the single most important factor in preventing two of a hospital’s costliest problems: medication waste and accidental exposure. An accidental needle disconnection can be catastrophic.

Top Applications for Luer Lock Syringes

As a rule, if a needle failure would result in a significant clinical risk or financial loss, you should be specifying Luer Lock.

- Chemotherapy Administration: Handling cytotoxic drugs requires the highest level of safety.

- IV Therapy & Infusion Pumps: For continuous, long-term infusions, a secure connection is essential.

- High-Pressure Injections: When administering viscous fluids or contrast media.

- Blood Draws: Especially from difficult veins or arterial lines.

- Critical Medication Delivery: Any scenario where precise, uninterrupted dosage is paramount.

Deep Dive: Luer Slip Syringes — The Champion of Speed and Simplicity

A Luer Slip syringe has a smooth, tapered tip with no threads. Attaching a needle is as straightforward as it gets: just push the hub onto the tip. The connection is held in place purely by the friction between the two tapered surfaces.

Key Advantage: Speed and Ease of Use

In a high-volume, fast-paced environment, every second counts. The few seconds saved by not having to twist on each needle add up to a significant improvement in workflow efficiency.

For routine, repetitive tasks, the Luer Slip’s push-on, pull-off action is undeniably faster and can even reduce hand fatigue for clinicians performing dozens of injections per shift.

Top Applications for Luer Slip Syringes

Luer Slip syringes are the workhorses for low-pressure, low-risk procedures. They are a cost-effective and efficient choice for:

- Vaccinations: Flu shots, COVID-19 vaccines, and other routine immunizations.

- Subcutaneous Injections: Perfect for administering medications like insulin or heparin.

- Simple Intramuscular Injections: For non-viscous medications.

- Flushing Wounds or Catheters: When using saline to clean an area.

- Laboratory Fluid Transfer: For aspirating or dispensing non-hazardous fluids.

Head-to-Head Comparison: A Data-Driven Decision Matrix

As a procurement professional, you need more than just definitions; you need a clear, comparative framework to justify your purchasing decisions. This table translates technical features into procurement takeaways.

| Feature | Luer Lock Syringe | Luer Slip Syringe | Procurement Takeaway & Strategic Consideration |

|---|---|---|---|

| Connection Security | Excellent: Threaded lock provides a robust, stable connection. | Fair: Friction fit is adequate for low-pressure use but can fail. | Choose Luer Lock for all critical, high-pressure, or hazardous fluid applications. The risk of failure with a Luer Slip in these scenarios is too high. |

| Speed of Assembly | Slower: Requires a deliberate twisting motion. | Faster: A simple push-on, pull-off connection. | For high-volume, routine tasks (e.g., vaccination clinics), Luer Slip can significantly improve workflow efficiency. |

| Leak Prevention | Excellent: The secure, threaded seal creates a closed system. | Moderate: Higher potential for minor leakage if not fitted perfectly. | Luer Lock is superior for reducing medication waste and preventing exposure to hazardous substances. |

| Ideal Use Cases | IV therapy, chemotherapy, viscous fluids, contrast media, automated infusions. | Vaccinations, insulin injections, routine IM/subcutaneous injections, wound flushing. | Match the syringe type directly to the clinical application’s risk profile. Standardize policies to prevent incorrect usage. |

| Cost | Higher: More complex manufacturing process. | Lower: Simpler design leads to lower manufacturing costs. | Balance initial cost against the total cost of ownership. The higher price of a Luer Lock is easily justified if it prevents a single adverse event. |

A Procurement Framework: 3 Questions to Ask Before You Buy

To standardize your purchasing and ensure you make the right choice every time, build your decision-making process around these three critical questions.

1. What is the Clinical Application and Its Associated Risk?

Work with your clinical teams to classify procedures. For high-risk applications (ICU, chemotherapy, hazardous materials), the choice is simple: Luer Lock. For low-risk, routine procedures, a Luer Slip may be a cost-effective option.

2. What are the Fluid’s Properties and the Required Pressure?

The physics of the injection matter. For thick, viscous medications or any high-pressure application (including automated pumps), always default to Luer Lock to prevent dangerous disconnections.

3. What is the True Cost of Ownership (TCO)?

Don’t just look at the line-item price. Calculate the potential “cost of failure,” including wasted medication, cleanup costs, and staff injury. You’ll often find the slightly more expensive Luer Lock is the far more economical choice.

Beyond the Tip: Don’t Forget These Critical Quality Checks

Your job isn’t done after choosing the connection type. Insist on ISO 80369 Compliance as your ultimate guarantee of quality, safety, and interoperability. Evaluate material quality (medical-grade polypropylene) and validated sterilization methods (e.g., Ethylene Oxide gas).

A Final Word: Your Supplier is Your Partner in Safety

Choosing the right syringe type is a huge step. But partnering with a manufacturer who understands these nuances, provides a stable supply chain, and offers transparent documentation is just as important. A reliable partner helps you manage risk, optimize costs, and ultimately, contribute to better patient care.